www.mexicoindustrial.net

17

'19

Written on Modified on

Renishaw, soluciones integrales para la industria 4.0 en Advanced Factories.

Es un hecho que la industria está evolucionando a pasos agigantados y en la actualidad se exigen soluciones integrales tales como el Big Data, la inteligencia artificial, la automatización, elementos de medición más eficientes y la tan disruptiva fabricación aditiva que faciliten los procesos de fabricación.

C.I.A operates in a modern structure with a covered production area of 2300 sqm, equipped with the latest equipment and machine tools. The commercial and administrative offices and the mechanical and electronic design departments cover an area of 750 sqm. The company has two-dimensional, three-dimensional, electrical and electronic CAD systems and programming software for all the main kinds of PLCs, robots and supervisors.

A staff of engineers and mechanical, electronic and IT technicians develop all the projects and write the documents which are filed according to CE standards, while a group of specialised technicians and fitters carry out the assembly, testing and any maintenance of all the equipment produced. C.I.A. is a certified company with a computerised system which can guarantee the immediate retrieval of any information from any of its systems quickly and easily even after several years have passed.

High value added

“Our company is involved in industrial automation in general and with robotised automation in particular”, Mr Galimberti said. “We produce a number of different systems for a vast range of applications. For example, we operate in sectors ranging from the pharmaceutical industry to packaging, foodstuffs, the mechanical sector, and so on.”

“Almost all our applications are specific to some extent, because we deal with special equipment, produced ad hoc according to the customer’s specific requirements”, continued the director of C.I.A. “So we are like system integrators, since we design and integrate automation systems intended for all over the world.” Some examples of applications implemented in various sectors can be seen on the company’s website (www.ciaautomazione.it).

During the recent BIMU (the biennial machine tools fair) held in Milan last October, C.I.A. Automation and Robotics was represented on the ITIA CNR (National research council) stand, where it showcased some highly innovative systems characterised by the use of advanced technologies such as laser scanners, stereoscopic vision equipment and systems that can reproduce a die and copy it directly, automatically recomposing the scanning scattergrams. “No other company in Europe can offer this technology, which we have patented together with CNR”, Mr Galimberti stressed. “Ours is a long-standing collaboration relationship. We have funded some of CNR’s research and have produced robotised stations for various kinds of processing, while some of CNR’s researchers have been involved in innovative developments and mathematical calculations. Even in the simplest of applications, such as the robotised loading/unloading of machine tools, we work with the same level of attention which has enabled us to develop these high-level applications.”

The value added of C.I.A.’s solutions is above all in its ability to automate production cycles using advanced systems so as to make Italian companies competitive on the world market. It is a well-known fact that it is currently practically impossible to compete with factories in the East or China without automation: our labour costs are much too high and this is one of the reasons that many companies are moving their production overseas. With its automated systems, C.I.A. Automation and Robotics is trying to ensure that certain processing activities, which would not otherwise be feasible to carry out manually in Italy because they require too much manpower, can compete with similar activities provided by far eastern countries.

Opting for flexibility

C.I.A. Automation & Robotics got to know about HMS products and especially the line of Anybus-X-Gateway converters a few years ago, through a supplier of automation components. “We started using HMS devices in our applications almost straight away”, explained Mr Galimberti, who added: “Very often, we have to interface different kinds of devices in our automatic systems that use different communication protocols. For example, we typically use robots with DeviceNet interface and PLCs with Profibus interface. This need for flexibility in diverse design conditions led us to try HMS products, which we appreciated immediately because they are particularly comprehensive and can be used to interface different kinds of machines, even pre-existing machinery.”

Before opting for HMS products through EFA Automation, the exclusive distributors for Italy of HMS’s GATEWAY solutions, the Albiate-based company also assessed what other suppliers had to offer. Selection criteria centred around the functionality and flexibility of the devices in particular, but the performance/price ratio was also part of the equation. The technical and economic features of the HMS Anybus family came out on top and C.I.A. has effectively adopted these devices on a permanent basis.

“We have produced various equipment with Profibus master PLCs and DeviceNet slaves, or with DeviceNet master PLCs and Profibus slaves, and so on”, said Galimberti. “HMS products have enabled us to resolve and simplify a number of these applications. The protocols we use the most are Profibus and DeviceNet, which cover almost 90% of the cases we deal with involving robots and PLCs.”

He added that C.I.A. was satisfied with the performance of HMS products and that no major problems were encountered. “I believe that we will continue to find space for HMS products in our future applications, whenever we need to interface system parts that use different communication protocols”, concluded the director of C.I.A. Automation & Robotics.

About C.I.A. Automation and Robotics

Located in Albiate just outside Milan, C.I.A. Automation and Robotics has been operating in the field of advanced industrial automation for 30 years, during which it has been involved in various aspects of the production process: handling of materials, loading/unloading of automatic machinery, palletisation/depalletisation, component dosing, process management and monitoring, on-line testing of finished products, and so on. Throughout this time span, the company has developed the use of innovative technologies, applied to resolve problems relating to production and industrial processes. C.I.A. Automation and Robotics engineers, produces and assembles manipulators and Cartesian, Scara and anthropomorphic robots; the company specialises in loaders and feeders, dosers and refillers, electronic equipment for the automation and supervision of systems and machinery, testing and quality control systems, assembly stations and special machinery in general.

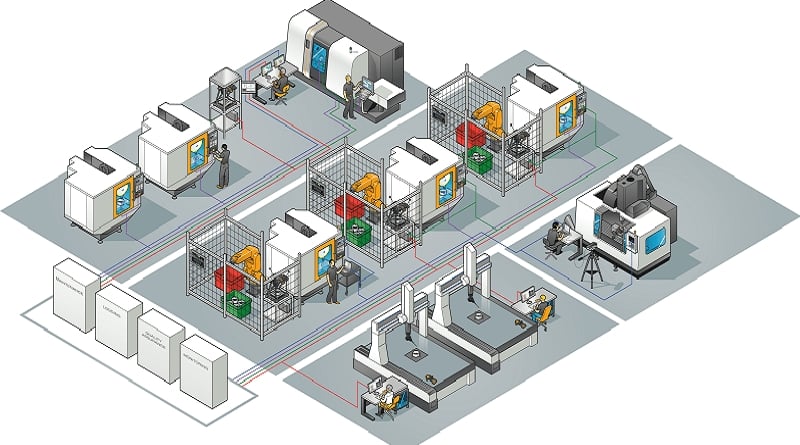

Caption 1: C.I.A. Automation and Robotics develops advanced automation systems including innovating measuring features.

Caption 2: Anybus X-Gateway allows flexibility in industrial communication interfaces.