www.mexicoindustrial.net

28

'17

Written on Modified on

Más difícil imposible

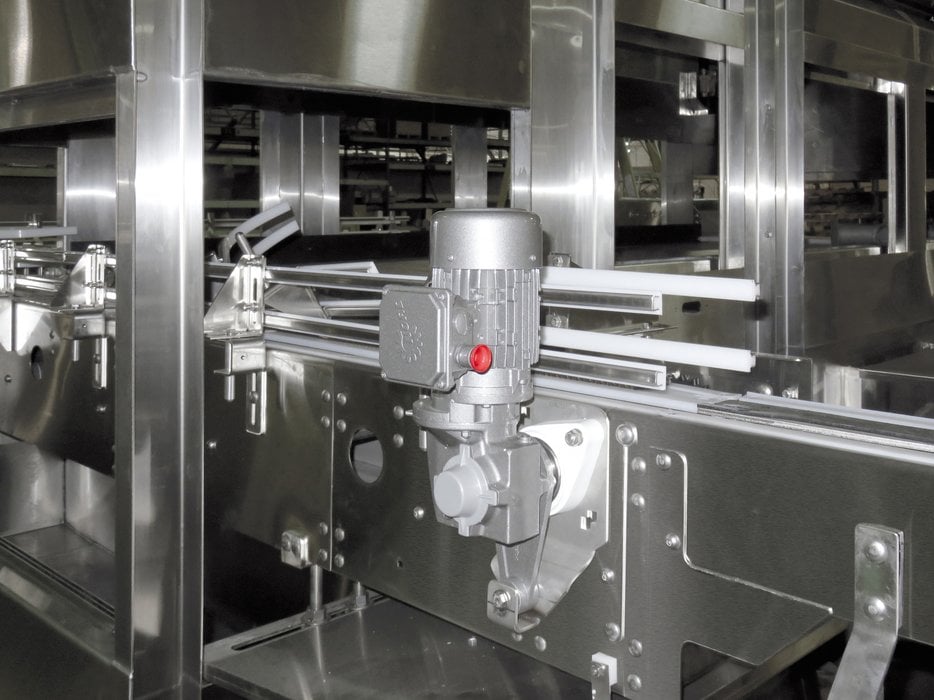

Tecnología de accionamiento robusta para túneles de refrigeración y pasteurizadores

For more than 65 years, Gravograph has pioneered high-quality, durable engraving and marking machines and materials. Some of its major innovations include: UNICA (the first autonomous engraving machine that works without the need to connect to a PC); GravoStyle (the first engraving software that works on Windows); and GravoStyle ‘98 (an engraving software that enables 3-dimensional engraving). Strong growth in the North American division over the last five years has led to some necessary improvements in the company’s US division – which now employs 115 people, including 50 in sales and marketing.

“We had some quality issues three or four years ago,” says Tim Grabrovaz, who manages Gravograph’s US, Canadian and Australian operations. “All the action plans we have set, representing a US$1 million investment each year, now puts us in the top level of quality.” The main elements of the improvement plan were: a Kaizen approach (continuous improvement through measurement, discussion and action) to logistics and customer service.

The company has deployed the Kaizen method at its plant in Duluth, Georgia, which processes 300 orders per day. The move was strongly supported by the management, and its effects have been felt across the business – from productivity study groups to production workshops. Of 181 action items identified in 2007, 133 have been completed and 48 are still in progress. Gravograph is also banking on the ‘intelligent factory’, which makes use of the know-how of all employees. Around 10 employee suggestions are put into effect each month. These ideas include: monitoring daily sales results, weekly inventory, introducing telephone metrics, and ensuring that orders are placed within supplier lead times.

Regarding Logistics and Supply Network the company has created third party supply networks to save inventory and shipping costs, while expanding its product offerings and improving response time. It has also improved the process to coordinate parts delivery and the arrival of field technicians. These operations are now centrally coordinated to optimize logistics – and give an exact arrival time for a technician (which was estimated previously). All processes are now computerized – with full traceability from procurement to shipment at all sites. As a result, the average inbound delivery time has been cut in half – from 8 weeks to 4 weeks. The accuracy of technician on-site arrival has improved by 80%, and the delay was also halved.

Gravograph also focuses on the way that it handles the 300-400 daily enquiries that it receives. The Single Point of Contact (SPOC) program has been set in order to improve customer relations through employee training and "ownership of customer resolution" style of customer care. It applies to most types of customer enquiry, including technical service. Each representative now retains ownership of the issue throughout the resolution process and remains the point of contact for the customer – even if the issue requires expertise from others within the organization. There is full event traceability and monitoring. Data from the SPOC log are analyzed each week to spot quality integrity issues and training opportunities. The representative gathers as much detail as possible, to avoid having to call the customer back later for more information.

As a result of these three main improvement actions, there was an 80% increase in the technical support fulfilled call status and Returned Goods (RGA) saw massive improvement – reduced by 85% in just three years. There has also been a huge reduction in back orders.

Marketing is also being extended and improved. This includes the launch of three new catalogues, for Laserable Wood and Engravables, as well as a Materials catalogue showing the extended range in a simpler, more informative way. At the same time, weekly eblasts (email) inform customers of new technologies and tips to help grow their business. All brochures and catalogues are also now updated electronically, so that the latest information is always readily available electronically or to be printed.

The Gravograph group has also progressed in the worldwide comprehensive service and the way it manages large customer accounts. Operating in more than 50 countries, through 23 subsidiaries and more than 300 agents and distributors, Gravograph is the only company on the market able to provide the same logistics, services, products and knowledge base – everywhere in the world – to large international companies. No other competitive company offers this complete solution.

“With the current economic context it is important to plan and implement strong growth programs for the next few years. We know that our efforts improving quality, service and customer care will be major factors that provide value to our customers,” says Grabrovaz.

Gravograph Australia has initiated a similar program. The company, which has 5,000 customers, spent around US$120,000 reorganizing its warehouse. The logistical process was analyzed, new equipment and infrastructure installed and the whole process reengineered. This led to more efficient picking and packing of materials, while reducing errors. It also helped the plant to meet safety standards. A cool room was added to maintain quality of its Clear Glaze products during the hot Australian summers and proved a safe room for dangerous goods. Gravograph also invested in corrugated cardboard packaging for material shipments. This increased the upfront cost to Gravograph but has decreased the amount of damaged goods and has saved money and increased customer service.

Gravograph is focused on continuous improvement.

“We had some quality issues three or four years ago,” says Tim Grabrovaz, who manages Gravograph’s US, Canadian and Australian operations. “All the action plans we have set, representing a US$1 million investment each year, now puts us in the top level of quality.” The main elements of the improvement plan were: a Kaizen approach (continuous improvement through measurement, discussion and action) to logistics and customer service.

The company has deployed the Kaizen method at its plant in Duluth, Georgia, which processes 300 orders per day. The move was strongly supported by the management, and its effects have been felt across the business – from productivity study groups to production workshops. Of 181 action items identified in 2007, 133 have been completed and 48 are still in progress. Gravograph is also banking on the ‘intelligent factory’, which makes use of the know-how of all employees. Around 10 employee suggestions are put into effect each month. These ideas include: monitoring daily sales results, weekly inventory, introducing telephone metrics, and ensuring that orders are placed within supplier lead times.

Regarding Logistics and Supply Network the company has created third party supply networks to save inventory and shipping costs, while expanding its product offerings and improving response time. It has also improved the process to coordinate parts delivery and the arrival of field technicians. These operations are now centrally coordinated to optimize logistics – and give an exact arrival time for a technician (which was estimated previously). All processes are now computerized – with full traceability from procurement to shipment at all sites. As a result, the average inbound delivery time has been cut in half – from 8 weeks to 4 weeks. The accuracy of technician on-site arrival has improved by 80%, and the delay was also halved.

Gravograph also focuses on the way that it handles the 300-400 daily enquiries that it receives. The Single Point of Contact (SPOC) program has been set in order to improve customer relations through employee training and "ownership of customer resolution" style of customer care. It applies to most types of customer enquiry, including technical service. Each representative now retains ownership of the issue throughout the resolution process and remains the point of contact for the customer – even if the issue requires expertise from others within the organization. There is full event traceability and monitoring. Data from the SPOC log are analyzed each week to spot quality integrity issues and training opportunities. The representative gathers as much detail as possible, to avoid having to call the customer back later for more information.

As a result of these three main improvement actions, there was an 80% increase in the technical support fulfilled call status and Returned Goods (RGA) saw massive improvement – reduced by 85% in just three years. There has also been a huge reduction in back orders.

Marketing is also being extended and improved. This includes the launch of three new catalogues, for Laserable Wood and Engravables, as well as a Materials catalogue showing the extended range in a simpler, more informative way. At the same time, weekly eblasts (email) inform customers of new technologies and tips to help grow their business. All brochures and catalogues are also now updated electronically, so that the latest information is always readily available electronically or to be printed.

The Gravograph group has also progressed in the worldwide comprehensive service and the way it manages large customer accounts. Operating in more than 50 countries, through 23 subsidiaries and more than 300 agents and distributors, Gravograph is the only company on the market able to provide the same logistics, services, products and knowledge base – everywhere in the world – to large international companies. No other competitive company offers this complete solution.

“With the current economic context it is important to plan and implement strong growth programs for the next few years. We know that our efforts improving quality, service and customer care will be major factors that provide value to our customers,” says Grabrovaz.

Gravograph Australia has initiated a similar program. The company, which has 5,000 customers, spent around US$120,000 reorganizing its warehouse. The logistical process was analyzed, new equipment and infrastructure installed and the whole process reengineered. This led to more efficient picking and packing of materials, while reducing errors. It also helped the plant to meet safety standards. A cool room was added to maintain quality of its Clear Glaze products during the hot Australian summers and proved a safe room for dangerous goods. Gravograph also invested in corrugated cardboard packaging for material shipments. This increased the upfront cost to Gravograph but has decreased the amount of damaged goods and has saved money and increased customer service.

Gravograph is focused on continuous improvement.